Application of microwave-assisted fragmentation in excavation and comminution of hard rocks/ores

Enhancement of mineral resources employment efficiency is one of the main targets identified by the mining sector and United Nation’s sustainable development roadmaps.

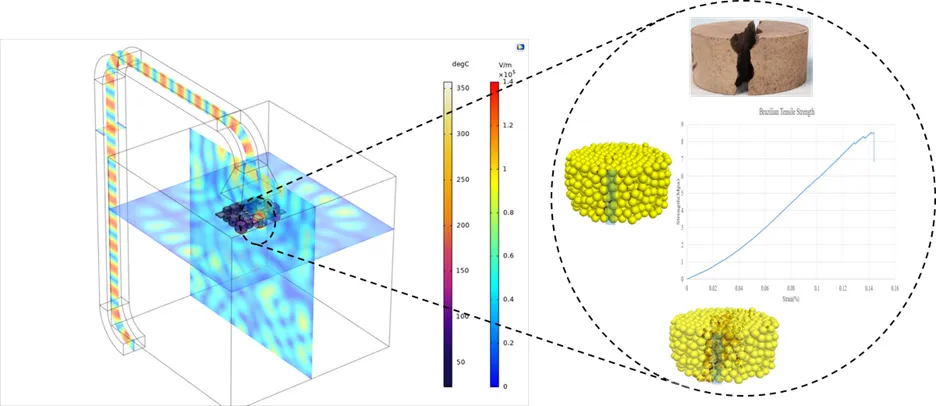

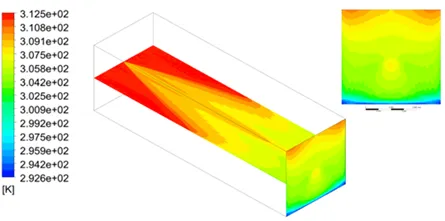

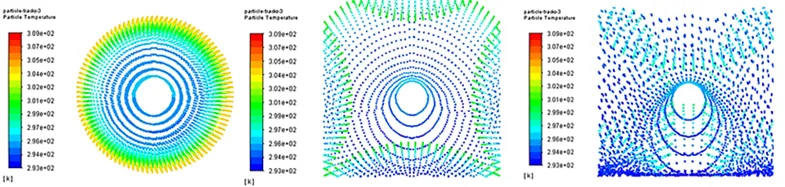

However, the relatively low energy efficiency of rock fragmentation, including excavation/comminution, is among the most challenging mining industry hurdles. The microwave pre-treatment technique has yielded promising results compared to other pre-weakening solutions such as high-temperature rock cutting, electro-pulse defragmentation and hydrofracking. So far, the importance of the energy used in creating microwave-induced fractures is mostly overlooked. The primary goal of our research is to connect energy consumption and strength reduction by using numerical methods. Towards this end, A COMSOL-based numerical tool has been developed to simulate the microwave-treatment process taking place within the cavity. In addition to this Finite Element Method (FEM) tool, a Discrete Element Modelling (DEM) tool has been developed to evaluate the behavior of rocks undergoing microwave treatment. These numerical tools will be used to better understand rock fragmentation and macro-scale responses to achieve energy viability in microwave-assisted rock fragmentation processes.

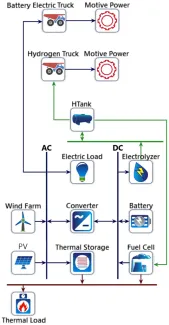

Mine hybrid renewable energy system for application in remote mines

Mining is to be considered as one of the most energy-intensive industrial activities in Canada.

Due to its high fossil fuel dependency, the mining sector is one of the primary contributors of carbon emissions from Canadian industry (82.6 megatons in 2017 according to Natural Resources Canada). Consequently, miners are seeking more innovative solutions for fully transitioning their energy supply off fossil fuels especially in remote mines where lack of access to electric grid and natural gas makes them solely rely on fossil fuels for provision of power, haulage and heat. Renewable energy systems such as wind and solar photovoltaic can relieve this over-reliance on fossil fuels. Although some progresses have been made to shift towards green energies, high cost of battery storage system makes the current mine renewable solutions economically non-competitive with the conventional diesel-based systems. Using hydrogen and thermal storage systems due their relatively cheaper technologies can facilitate the application of renewable energies in mining industry. In this project we aim to develop a novel integrated renewable-multi storage (Battery/Hydrogen/Thermal Storage) solution for provision of fully-decarbonized energy in off-grid mining operations.

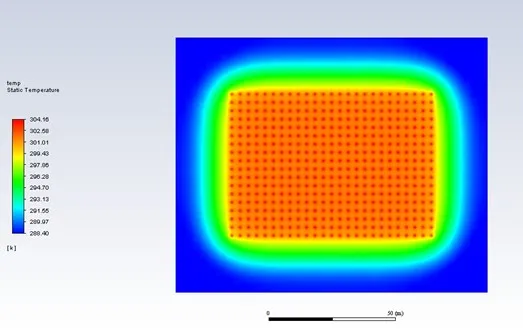

Design of integrated solar-borehole thermal storage systems

In this research project, we plan to design, develop, and optimize the solar-borehole thermal energy storage system to supply a complete heating solution to a residential high-rise building located in a cold climatic region like Canada.

Solar thermal collector system absorbs the solar thermal energy year-round which is mostly stored during the summer days in underground through borehole heat exchangers. The stored energy is extracted during the winter months to supply the building heat demand. This research underlines the seasonal intermittency issues with renewable heating systems which can be effectively dealt by use of borehole thermal energy storage systems. A numerical simulation code is developed to couple the solar thermal collector system with the borehole thermal energy storage system. This code aims to study and explore the heat transfer mechanisms involved in the integrated system to gain a better understanding and enhance the performance of the system.

Spray cooling and heat recovery in mine ventilation

For deep mineral deposits, underground mining methods generously offer numerous options for feasible extraction of valuable minerals.

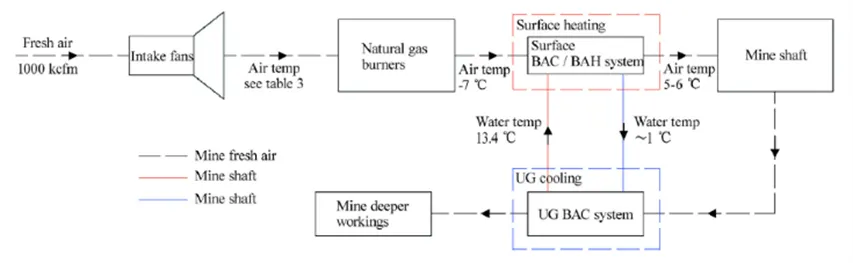

On one hand, these options are rather flexible and could yield comparably smaller environmental footprints than some of the other bulk mining methods. Also, it is observable that underground mining operations are continuously increasing in number due to slow but gradual depletion of shallower deposits. On the other hand, increasing depth of these workings requires employment of advanced mechanical ventilation and air conditioning techniques. This brings several challenges to the industry in terms of finding ‘low cost / high performance’ options, as these systems are often energy intensive and expensive to acquire. Here, mine ventilation research team at the NBK Mining takes the duty to bring scientific research in these terms to develop an understanding of such systems and bring novel solutions to the industry supported by the contemporary research methods.)

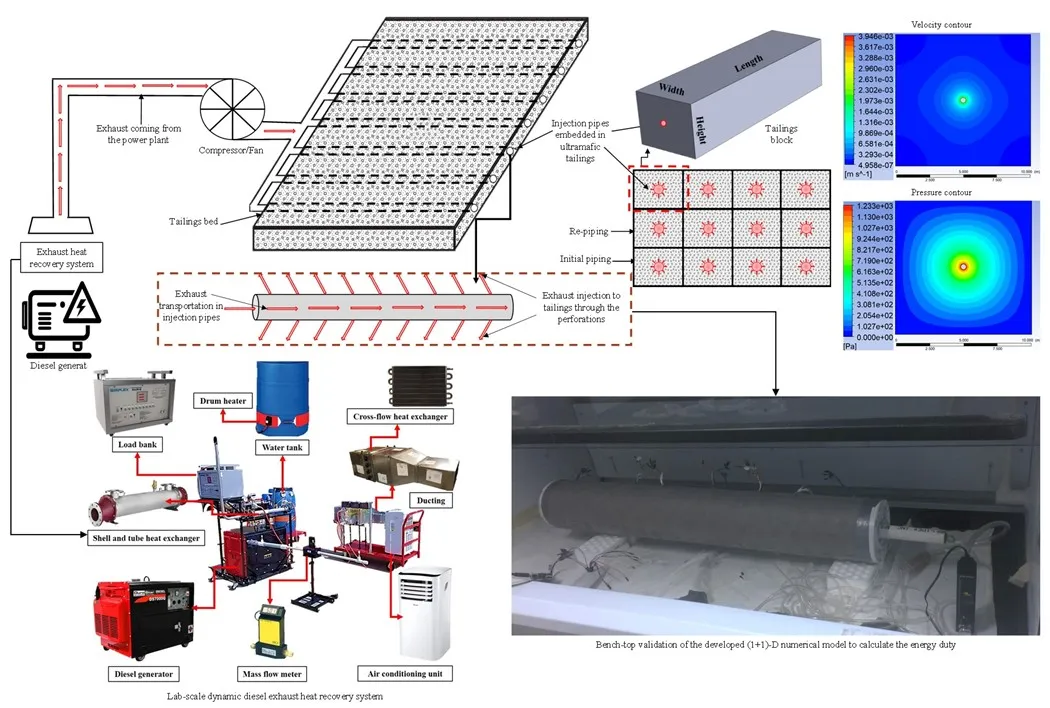

Numerical and experimental investigation of fluid flow and heat transfer of flue gas carbon sequestration in mine wastes

Being the most bountiful anthropogenic greenhouse gas, carbon dioxide has been significantly enhancing global warming.

Ultramafic mine tailings, with their rich Mg and Ca content, can capture and store carbon in solid form through mineral carbonation. There is a great potential of reducing the carbon footprint of the off-grid mines that have fossil fuel-based power generation plants by injecting flue gas in the available ultramafic mine tailings. To access the applicability of the concept, techno-economics is currently being investigated through numerical and experimental studies. An amenable engineering tool is under development to estimate the energy/costs associated with injection of flue gas for the purpose of carbon sequestration of in main tailings.